Inqubo yokusakaza nokukhanga

Ekwenziweni kwensimbi, ukusakaza kuyinqubo lapho insimbi ewuketshezi ilethwa esikhunjeni (imvamisa nge-crucible) equkethe umbono ongemuhle (okungukuthi, isithombe esinegethivu esinezinhlangothi ezintathu) somumo ohlosiwe.Insimbi ithululelwa esikhunjeni ngokusebenzisa umsele ongenalutho okuthiwa i-sprue.Insimbi nesikhunta sibe sesipholile, futhi ingxenye yensimbi (i-casting) iyakhishwa.Ukusakaza kuvame ukusetshenziselwa ukwenza izimo eziyinkimbinkimbi ezingaba nzima noma ezingenayo imali ukuzenza ngezinye izindlela.

Izinqubo zokulingisa zaziwa izinkulungwane zeminyaka, futhi bezisetshenziswa kabanzi ekuqopheni (ikakhulukazi okwethusi), ubucwebe bezinsimbi eziyigugu, nezikhali namathuluzi.Ukulingisa okuklanywe kakhulu kutholakala kumaphesenti angu-90 wezimpahla ezihlala isikhathi eside, okuhlanganisa izimoto, amaloli, indiza, izitimela, izimayini nemishini yokwakha, imithombo kawoyela, izinto zikagesi, amapayipi, amapayipi amanzi, izinjini zomoya, izitshalo zenuzi, izinto zezokwelapha, imikhiqizo yokuzivikela, amathoyizi, kanye Okuningi.

Amasu omdabu ahlanganisa ukuphonswa kwengcina okulahlekile (okungase kuphinde kuhlukaniswe ngokusakazwa kwe-centrifugal, nokusiza kwe-vacuum ukuthela okuqondile), ukubunjwa kwesikhunta se-plaster kanye nokusakazwa kwesihlabathi.

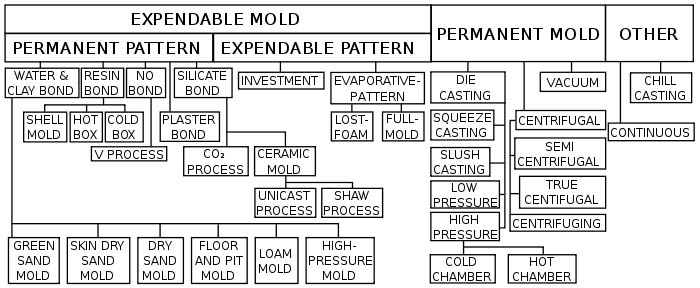

Inqubo yesimanje yokulingisa ihlukaniswe yaba izigaba ezimbili eziyinhloko: ukusakaza okusebenzisekayo nokungasebenziseki.Iphinde ibhidlizwe ngezinto zokubumba, njengesihlabathi noma insimbi, kanye nendlela yokuthela, njenge-gravity, vacuum, noma umfutho ophansi.

I-Forging iwuhlelo lokukhiqiza olubandakanya ukubunjwa kwensimbi kusetshenziswa amandla okucindezela asendaweni.Amagalelo alethwa ngesando (ngokuvamile isando samandla) noma idayizi.Ukuqamba kuvame ukuhlukaniswa ngokwezinga lokushisa okwenziwa ngalo: ukubumba okubandayo (uhlobo oluthile lokusebenza okubandayo), ukubumba okufudumele, noma ukubumba okushisayo (uhlobo lomsebenzi oshisayo).Kulezi ezimbili zokugcina, insimbi iyashiswa, imvamisa ibe yi-forge.Izingxenye ezifojiwe zingaba nesisindo esisuka ngaphansi kwekhilogremu ukuya kumakhulu amathani wemethrikhi.Ukuqamba kwenziwa ngabakhandi bensimbi iminyaka eyinkulungwane;imikhiqizo yendabuko kwakuyizinto zasekhishini, i-hardware, amathuluzi esandla, izikhali ezisogwini, amasimbali, nobucwebe.Kusukela kuNguquko Yezimboni, izingxenye ezifojiwe zisetshenziswa kakhulu ezindleleni nasemishinini nomaphi lapho ingxenye idinga amandla aphezulu;ama-forging anjalo ngokuvamile adinga ukucutshungulwa okwengeziwe (njengokwenza imishini) ukuze kuzuzwe ingxenye ecishe iqedwe.Namuhla, ukuqamba kuyimboni enkulu emhlabeni wonke

Ukubunjwa kwesikhunta okuthengekayo ukuhlukaniswa okujwayelekile okuhlanganisa isihlabathi, ipulasitiki, igobolondo, ukhonkolo, kanye nokubumba okutshalwa kwezimali (okulahlekile kwe-wax).Le ndlela yokubunjwa kwesikhunta ibandakanya ukusetshenziswa kwesikhunta sesikhashana, esingasebenziseki kabusha.

Ukulingisa isihlabathi

Ukubunjwa kwesihlabathi kungenye yezinhlobo ezidume kakhulu nezilula zokulingisa, futhi sekusetshenziswe amakhulu eminyaka.Ukufakwa kwesihlabathi kuvumela amaqoqo amancane kunokubunjwa kwesikhunta unomphela futhi ngezindleko ezizwakalayo.Le ndlela ayigcini nje ngokuvumela abakhiqizi ukuthi benze imikhiqizo ngenani eliphansi, kodwa kunezinye izinzuzo zokuphonsa isihlabathi, njengokusebenza kosayizi omncane kakhulu.Inqubo ivumela ukulingisa kuncane ngokwanele ukungena entendeni yesandla somuntu kuleyo mikhulu ngokwanele imibhede yesitimela kuphela (ukulingisa okukodwa kungakha umbhede wonke wemoto eyodwa yesitimela).Ukubunjwa kwesihlabathi nakho kuvumela izinsimbi eziningi ukuthi ziphonswe kuye ngohlobo lwesihlabathi esisetshenziselwa isikhunta.

Ukubunjwa kwesihlabathi kudinga isikhathi sokuhola sezinsuku, noma ngisho namasonto ngezinye izikhathi, ukuze kukhiqizwe ngezinga eliphezulu lokukhipha (izingcezu ezingu-1–20/hr-mold) futhi akudlulwa ekukhiqizeni ingxenye enkulu.Isihlabathi esiluhlaza (esimanzi), esimnyama ngombala, cishe asinaso ingxenye yomkhawulo wesisindo, kuyilapho isihlabathi esomile sinengxenye engokoqobo yomkhawulo wesisindo esingu-2,300–2,700 kg (5,100–6,000 lb).Isisindo sengxenye encane sisuka ku-0.075–0.1 kg (0.17–0.22 lb).Isihlabathi sihlanganiswa kusetshenziswa ubumba, izibophezelo zamakhemikhali, noma amafutha enziwe nge-polymerized (njengamafutha emoto).Isihlabathi singagaywa kabusha izikhathi eziningi emisebenzini eminingi futhi sidinga ukulungiswa okuncane.

Ukubunjwa kwe-loam

Ukubumba i-loam kusetshenziswe ukukhiqiza izinto ezinkulu ezilinganayo njengenganononi nezinsimbi zesonto.Loam inhlanganisela yobumba nesihlabathi notshani noma ubulongwe.Imodeli yezinto ezikhiqiziwe zakhiwa endaweni ethambile (i-chemise).Isikhunta sakhiwe sizungeze le khemisi ngokuyimboza nge-loam.Lokhu bese kubhakwa (kuxoshwe) bese kukhishwa ikhemisi.Isikhunta sibe sesimiswa siqonde emgodini ophambi kwesithando ukuze kuthelwe insimbi.Ngemva kwalokho isikhunta siyaphulwa.Ngakho-ke isikhunta singasetshenziswa kanye kuphela, ukuze ezinye izindlela zikhethwe ngezinjongo eziningi.

Ukwakhiwa kwe-plaster mold

I-Plaster casting ifana nokubunjwa kwesihlabathi ngaphandle kokuthi i-plaster of paris isetshenziswa esikhundleni sesihlabathi njengento yokubumba.Ngokuvamile, ifomu lithatha isikhathi esingaphansi kweviki ukuze lilungiswe, ngemva kwalokho kufinyelelwa izinga lokukhiqiza lamayunithi angu-1-10/hr-mold, nezinto ezinkulu njengo-45 kg (99 lb) nezincane njengo-30 g (1 oz) enesiphetho esihle kakhulu nokubekezelelana eduze.[5]I-Plaster casting iyindlela engabizi kwezinye izinqubo zokubumba zezingxenye eziyinkimbinkimbi ngenxa yezindleko eziphansi ze-plaster kanye nekhono layo lokukhiqiza eduze kwe-net shape castings.Okubi kakhulu ukuthi ingasetshenziswa kuphela ngezinto ezincibilikayo ezingenayo insimbi ephansi, njenge-aluminium, ithusi, i-magnesium, ne-zinc.

Ukubumba igobolondo

Ukubunjwa kwegobolondo kufana nokuphonsa isihlabathi, kodwa imbobo yokubumba yakhiwa "igobolondo" lesihlabathi eliqinile esikhundleni seflask egcwele isihlabathi.Isihlabathi esisetshenziswayo sicolekile kunesihlabathi sokujikijela isihlabathi futhi sixutshwa nenhlaka ukuze sikwazi ukushisisa ngephethini bese siqina sibe igobolondo elizungeze iphethini.Ngenxa ye-resin nesihlabathi esicolekile, sinikeza isiphetho esihle kakhulu.Inqubo i-othomathikhi kalula futhi inembe kakhulu kunokusakaza kwesihlabathi.Izinsimbi ezivamile eziphonswa zihlanganisa insimbi ekhonjiwe, i-aluminium, i-magnesium, nama-alloys ethusi.Le nqubo ilungele izinto eziyinkimbinkimbi ezincane kuya ezimaphakathi.

Ukutshala imali

Ukufakwa kwe-investimenti (okwaziwa ngokuthi i- lost-wax casting in art) kuyinqubo eseyenziwe izinkulungwane zeminyaka, kanti inqubo ye-wax elahlekile ingenye yezindlela zakudala ezaziwayo zokwakha insimbi.Kusukela eminyakeni engu-5000 edlule, lapho ingcina yezinyosi yenza iphethini, kuya kubuchwepheshe obuphezulu banamuhla, izinto eziphikisayo, nama-alloys akhethekile, ukulingisa kuqinisekisa ukuthi izingxenye zekhwalithi ephezulu zikhiqizwa ngezinzuzo ezibalulekile zokunemba, ukuphindaphinda, ukuguquguquka, nobuqotho.

Ukutshala imali kususelwa eqinisweni lokuthi iphethini itshaliwe, noma izungezwe, ngento ephikisayo.Amaphethini we-wax adinga ukunakekelwa okwedlulele ngoba awanamandla ngokwanele ukumelana namandla okuhlangana nawo ngesikhathi sokwenza isikhunta.Enye inzuzo yokutshala imali ukuthi i-wax ingasetshenziswa kabusha.

Inqubo ifanele ukukhiqizwa okuphindaphindekayo kwezingxenye zomumo wenetha kusuka ezinhlobonhlobo zezinsimbi ezihlukene kanye nama-alloys asebenza kahle.Nakuba ngokuvamile isetshenziselwa ukulingisa okuncane, le nqubo isetshenziselwe ukukhiqiza amafreyimu eminyango yendiza ephelele, anensimbi efika ku-300 kg kanye nokusakazwa kwe-aluminium kufika ku-30 kg.Uma kuqhathaniswa nezinye izinqubo zokulingisa ezifana ne-die casting noma ukwenza isihlabathi, kungaba inqubo ebizayo.Kodwa-ke, izakhi ezingakhiqizwa kusetshenziswa ukufakwa kwe-investment casting zingahlanganisa amakhonsathi ayinkimbinkimbi, futhi ezimeni eziningi izingxenye ziphonswa eduze komumo wengqikithi, ngakho zidinga ukusetshenzwa kabusha okuncane noma zingasasebenzi lapho sekuphonswe.

I-Forging ingakhiqiza ucezu olunamandla kunokulinganisa okufanayo noma ingxenye eyenziwe ngomshini.Njengoba insimbi yakheka phakathi nenqubo yokubumba, ukuthungwa kwayo okusanhlamvu kwangaphakathi kuyakhubazeka ukuze kulandele ukuma okujwayelekile kwengxenye.Ngenxa yalokho, ukuhlukahluka kokuthungwa kuyaqhubeka kuyo yonke ingxenye, okubangela ucezu olunezici zamandla ezithuthukisiwe.Ukwengeza, ama-forging angakwazi ukuzuza izindleko eziphelele eziphansi kunokuphonsa noma ukwenza.Uma kucatshangelwa zonke izindleko ezikhona emjikelezweni wokuphila womkhiqizo kusukela ekuthengeni kuya ekuholeni isikhathi sokusebenza kabusha, kanye nokufaka izindleko ze-scrap, nesikhathi sokuphumula nokunye ukucatshangelwa kwekhwalithi, izinzuzo zesikhathi eside zokukhohlisa zingadlula ukonga kwezindleko zesikhashana. okungase kuhlinzekwe ngezinto ezibunjiwe noma eziqanjiwe.

Ezinye izinsimbi zingase zenziwe ngokubanda, kodwa insimbi nensimbi cishe kuhlale kushisa.Ukubumba okushisayo kuvimbela ukuqina komsebenzi okungabangelwa ukwakheka okubandayo, okuzokwandisa ubunzima bokwenza imisebenzi yesibili yomshini ocezu.Futhi, ngenkathi ukuqina komsebenzi kungase kufiseleke kwezinye izimo, ezinye izindlela zokwenza ucezu lube lukhuni, njengokwelapha ukushisa, ngokuvamile lunomnotho futhi luyalawuleka.Ama-alloys avumela ukuqina kwemvula, njengamaningi ama-alloys e-aluminium kanye ne-titanium, angafakwa ngokushisa, alandelwe ukuqina.

Ukwakhiwa kokukhiqiza kubandakanya izindleko ezinkulu zemishini, amathuluzi, izinsiza kanye nabasebenzi.Endabeni ye-forging eshisayo, isithando somlilo esishisa kakhulu (ngezinye izikhathi esibizwa ngokuthi i-forge) siyadingeka ukuze kushise ama-ingots noma amabhilidi.Ngenxa yobukhulu bezando zokukhamba ezinkulu kanye nezingxenye ezingakhiqiza, kanye nezingozi ezikhona ekusebenzeni ngensimbi eshisayo, ngokuvamile kudingeka isakhiwo esikhethekile ukuze kugcinwe umsebenzi.Endabeni yokusebenza kokuwisa, kufanele kwenziwe izinhlinzeko zokudonsa ukushaqeka nokudlidliza okukhiqizwa yisando.Iningi lemisebenzi yokubumba lisebenzisa ama-metal-forming dies, okumele afakwe ngomshini ngokunembile futhi afakwe ngokushisa ngokucophelela ukuze alolonge kahle ucezu lokusebenza, kanye nokumelana namandla amakhulu ahilelekile.

Ukusakaza izingxenye nge

Inqubo yokwenza imishini ye-CNC

I-GGG40 yensimbi

Izingxenye zemishini ye-CNC

GS52 casting steel

izingxenye zomshini

Imishini engu-35CrMo

izingxenye ze-alloy forging